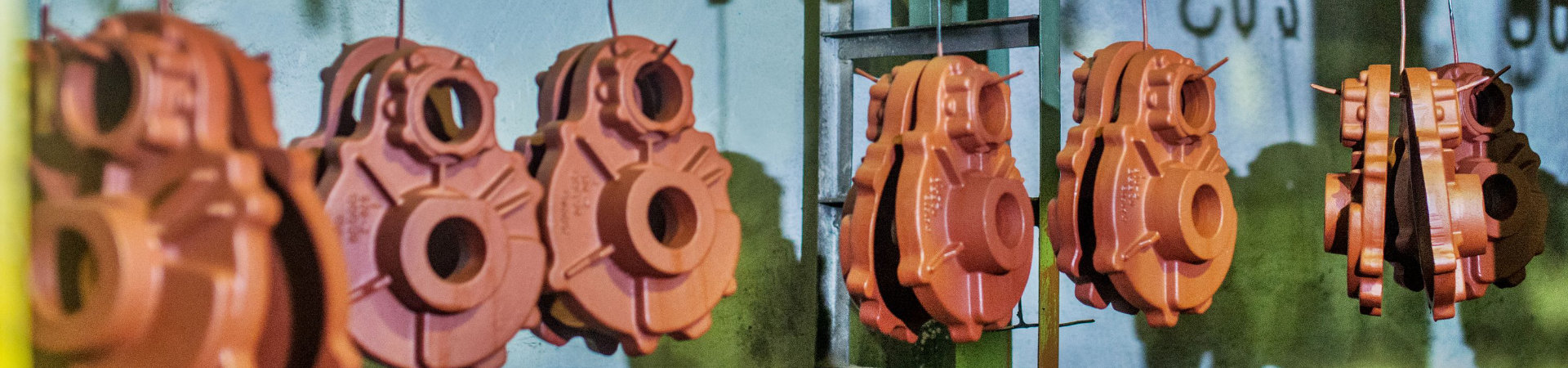

Castings

Currently, TERIEL's production capacity is 8,000 tons per year. We specialize in making small series: from 5 to 50 pieces and large: from 50 to 50,000 pieces, in the range from 0.5 to 150 kg.

Machine park:

- Induction furnaces - 2.8 and 3.8 t

- Automatic Hansberg box molding line 750x750x220 / 220

- Shaking molding machines 1000x800 * 350/350

- RÖPER-WERK H 2.5 cold core core shooters; H 5; H 12

- Hot core shooters

- Shot blast machines from STEM type B 10x12.5 S / W2C / SK / MS, CH 12x12.5 / 2W1E / SK / MS and type CH 12x18.5 / 3W1E / MS

- Grinding equipment

- SAVELLA mass processing station

We produce:

- Ductile iron castings EN-GJS-400-15, GJS-420-12, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-500-14, EN-GJS-600-3, EN-GJS-600-10, EN-GJS-700-2

- Gray iron castings EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300

Teriel sp.z o.o. recently implemented innovative technologies:

- Technology for producing high-quality ductile iron castings of the EN-GJS-400-18-LT, EN-GJS-350-22-LT grade with increased properties for use in extremely low temperatures (EN-GJS-400-18-LT up to -20o C , EN-GJS-350-22-LT up to -40o C) and iron castings with increased silicon content GJS-500-10.

- The technology of producing gray cast iron with increased mechanical properties, especially for the production of thin-walled castings.

We model for the needs of our clients from synthetic resins and metal.